Introduction

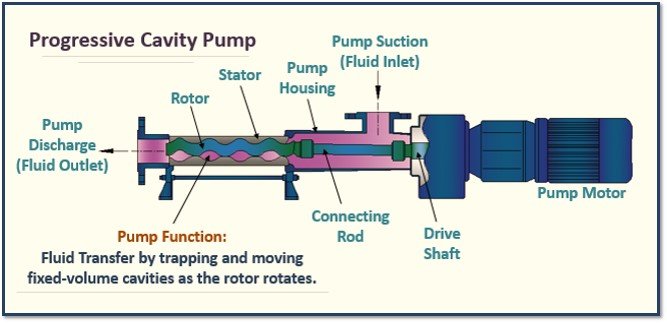

Progressive cavity pumps (PCP) are essential in various industries, ranging from oil and gas to food processing, chemical manufacturing, and wastewater treatment. These pumps have unique capabilities that make them ideal for handling challenging fluids such as slurries, viscous liquids, and more. In this comprehensive guide, we will explain what progressive cavity pumps are, their applications, how they work, and their differences from other types of pumps. We will also delve into when you should consider using a PCP and explore the various types available.

What is a Progressive Cavity Pump Used For?

Progressive cavity pumps are often referred to as positive displacement (PD) pumps because they move a fixed volume of liquid per cycle. They are used in industries where consistent flow rates and the handling of viscous or abrasive fluids are necessary. Common applications include:

-

Oil and Gas: PCPs are used to pump crude oil, drilling mud, and other high-viscosity fluids from wells.

-

Food and Beverage: They handle viscous liquids like chocolate, ketchup, and syrup without affecting product quality.

-

Wastewater Treatment: Used to pump sludge, slurry, and other thick fluids that need to be transported over long distances.

-

Chemical Manufacturing: Effective for pumping chemicals that may be sensitive to shear forces.

In these applications, progressive cavity pumps provide high efficiency, low pulsation, and accurate flow rates, making them indispensable in fluid handling operations.

What is the Difference Between Centrifugal and Progressive Cavity Pumps?

Centrifugal pumps and progressive cavity pumps (PCP) are both used to move fluids, but they operate on fundamentally different principles and are suited to different types of applications. Here’s a breakdown of the key differences:

-

Operating Principle:

-

Centrifugal Pumps: These pumps use a rotating impeller to add velocity to the liquid, converting this kinetic energy into pressure.

-

Progressive Cavity Pumps: These pumps rely on a rotating rotor inside a stator to move fluid. The cavity between the rotor and stator progresses, moving liquid through the pump.

-

-

Fluid Type:

-

Centrifugal Pumps: Best suited for clear liquids, like water, at lower viscosities and with minimal solids.

-

Progressive Cavity Pumps: Ideal for viscous, shear-sensitive liquids, as well as those with high solid content.

-

-

Flow Rate:

-

Centrifugal Pumps: The flow rate tends to vary with changes in system pressure.

-

Progressive Cavity Pumps: The flow rate remains consistent regardless of system pressure, making them suitable for applications that require steady, predictable flow.

-

What is the Difference Between a Progressive Cavity Pump and a Screw Pump?

The differences between a progressive cavity pump and a screw pump are subtle but important. Both are types of positive displacement pumps, but they differ in their design and operation:

-

Design:

-

Progressive Cavity Pump: It uses a helical rotor and stator, with the rotor moving fluid through the stator in a “progressive” manner.

-

Screw Pump: Consists of two or more interlocking screws that move fluid by pushing it along the axis of the pump.

-

-

Fluid Handling:

-

Progressive Cavity Pumps: Typically used for more viscous, slurry-like liquids and can handle solids in the fluid.

-

Screw Pumps: They are also capable of handling viscous fluids but are typically more suited for clean liquids and lighter fluids with lower solid content.

-

-

Efficiency:

-

Progressive Cavity Pumps: Often more efficient for handling thick fluids and those containing large particles.

-

Screw Pumps: Ideal for higher volume applications with a smoother, lower-viscosity flow.

-

What Are the Three Main Types of Pumps?

In fluid handling, three primary categories of pumps are commonly used:

-

Centrifugal Pumps: These pumps use rotational energy to move fluid, suitable for low-viscosity liquids.

-

Positive Displacement (PD) Pumps: This category includes progressive cavity pumps, gear pumps, and diaphragm pumps, which displace a fixed amount of fluid per cycle.

-

Peristaltic Pumps: These pumps move fluid by compressing and releasing a flexible tube, often used in laboratory or medical applications.

Each type has its advantages, and the choice depends on the nature of the fluid being pumped, flow rate requirements, and the system’s design.

What is Another Name for a Progressive Cavity Pump?

Progressive cavity pumps are also commonly referred to as “PC pumps” or “helical rotor pumps.” These names describe the rotor’s design and function, where the rotor and stator work together to create the progressive cavities that move the fluid.

When to Use a PD Pump?

A positive displacement pump (PD pump), such as a progressive cavity pump, is ideal when you need to handle:

-

Viscous Fluids: Thick liquids, slurries, or highly viscous products.

-

Non-Newtonian Fluids: Fluids whose viscosity changes depending on the applied stress.

-

Steady Flow: PD pumps provide a constant flow rate regardless of system pressure, which is essential in applications requiring uniform flow.

-

Shear-Sensitive Fluids: Liquids that cannot be exposed to shear forces, such as food products and pharmaceuticals.

In situations where precise flow control is essential, a PD pump is the preferred choice.

Which Type of Pump is Best?

The best pump type depends on the application. Here are some guidelines:

-

For low-viscosity, clean liquids: Centrifugal pumps are usually the best option due to their simplicity and cost-effectiveness.

-

For high-viscosity, shear-sensitive liquids: A progressive cavity pump is the best choice for precise control and gentle handling.

-

For slurry-like or abrasive fluids: A PD pump, such as a progressive cavity pump, is ideal for handling liquids with high solid content.

How Does a PD Pump Work?

A Positive Displacement (PD) pump works by trapping a fixed volume of fluid and displacing it through the pump with each cycle. In a progressive cavity pump, the rotor turns inside a stator, creating cavities that “progress” as the rotor turns, transporting fluid through the pump.

This pumping action ensures that the flow rate remains constant, regardless of the system pressure. It is particularly useful in applications requiring a steady and reliable flow of fluids.

Can Progressive Cavity Pumps Pump Water?

Yes, progressive cavity pumps can pump water, but they are typically used for more specialized applications. While they are capable of pumping clean water, they are better suited for thicker, viscous, or slurry-like fluids that centrifugal pumps may struggle with. For pure water, centrifugal pumps are often more efficient and cost-effective.

What Are the Two Types of Pump Cavitation?

Pump cavitation refers to the formation of vapor bubbles in the fluid as it moves through the pump. There are two main types of cavitation:

-

Non-Destructive Cavitation: This occurs at lower pressures and doesn’t cause significant damage to the pump components.

-

Destructive Cavitation: This occurs when the vapor bubbles collapse violently, leading to physical damage to the pump parts, such as pitting on the surfaces.

Both types of cavitation can affect the efficiency of a pump, and it is crucial to monitor and prevent cavitation in high-performance applications.

What is a DCP Pump?

A DCP pump refers to a “Diaphragm Cavity Pump”, which is a variant of the PCP. It uses a diaphragm to create a seal and move fluids. These pumps are typically used for handling chemicals, slurries, and other difficult fluids in various industries.

Conclusion

In conclusion, progressive cavity pumps are versatile, reliable, and efficient solutions for a wide range of industrial applications. Their ability to handle viscous, shear-sensitive, and abrasive fluids makes them indispensable in sectors like oil and gas, food and beverage, and wastewater treatment. Whether you need to understand the difference between centrifugal and progressive cavity pumps or want to know when to use a PD pump, this guide has covered all essential aspects to give you a thorough understanding.

2da12m