The HB 7736.8-2004 standard, titled “Test Method for Physical Properties of Composite Material Prepreg—Part 8: Determination of Tack,” is a pivotal document in the aerospace industry. Released on February 16, 2004, and implemented on June 1, 2004, this standard outlines the procedures for assessing the tackiness of composite material prepregs, which are essential in manufacturing high-performance aerospace components.

Significance of Tack in Composite Materials

Tack refers to the stickiness of a prepreg, determining its ability to adhere to surfaces during the lay-up process. Proper tack ensures that layers of composite materials remain in place before curing, which is crucial for achieving the desired mechanical properties and structural integrity in aerospace applications. Inadequate tack can lead to defects, compromising the performance and safety of the final product.

Overview of HB 7736.8-2004 Standard

The HB 7736.8-2004 standard provides a comprehensive methodology for evaluating the tack of composite prepregs. It specifies the sample preparation, testing environment, equipment requirements, and procedural steps to ensure consistent and reliable results. By adhering to this standard, manufacturers can maintain quality control and ensure that their materials meet the stringent requirements of the aerospace industry.

Sample Preparation and Testing Environment

According to the standard, samples should be prepared with dimensions of 300mm x 300mm. The testing environment must be controlled, typically at a temperature of 23°C and a relative humidity of 50%, to ensure that external factors do not influence the tack measurements. Maintaining these conditions is vital for obtaining accurate and reproducible results.

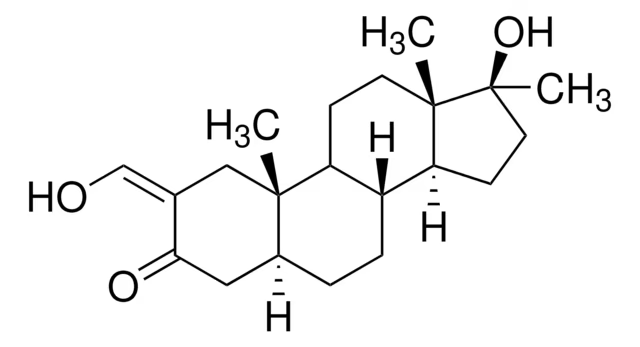

Testing Equipment and Procedure

The standard outlines the use of specific equipment, including a universal testing machine equipped with appropriate fixtures to hold the prepreg samples. The procedure involves compressing the sample to a specified pressure, holding it for a set duration, and then measuring the force required to separate the layers. This force is indicative of the prepreg’s tackiness.

Importance of Consistency in Testing

Consistency in testing is paramount to ensure that the prepreg materials perform as expected in real-world applications. The HB 7736.8-2004 standard emphasizes the need for uniform sample preparation, controlled environmental conditions, and precise execution of the testing procedure. Such consistency helps in identifying any variations in material properties that could affect the manufacturing process or the performance of the final composite structure.

Applications in the Aerospace Industry

In the aerospace sector, composite materials are extensively used due to their high strength-to-weight ratio. The tackiness of prepregs plays a critical role during the lay-up process of composite manufacturing. Ensuring optimal tack helps in achieving defect-free laminates, which are essential for the structural integrity of aerospace components. Adherence to the HB 7736.8-2004 standard ensures that the materials used meet the necessary quality benchmarks, thereby enhancing the safety and performance of aerospace vehicles.

Challenges in Tack Measurement

Measuring tack is inherently challenging due to its dependence on various factors such as resin content, ambient conditions, and handling techniques. The HB 7736.8-2004 standard addresses these challenges by providing a structured approach to minimize variability. However, operators must still exercise caution and ensure that all testing parameters are strictly controlled to obtain reliable data.

Advancements Since the Standard’s Publication

Since the release of HB 7736.8-2004, there have been advancements in both materials and testing methodologies. Researchers have explored new techniques to measure tack more accurately and efficiently. For instance, the compression-to-tension method has been developed as a quantitative approach to assess prepreg tack, offering improved repeatability and stability over traditional methods. This method evaluates the tack by measuring the energy required to separate compressed prepreg layers, providing a more comprehensive understanding of the material’s adhesive properties.

Global Relevance of HB 7736.8-2004

While HB 7736.8-2004 is a Chinese aerospace industry standard, its methodologies have influenced international practices in composite material testing. The principles outlined in the standard have been referenced in various research studies and have contributed to the development of global testing protocols. This cross-referencing underscores the standard’s significance in promoting uniformity and reliability in composite material assessments worldwide.

Accessing the HB 7736.8-2004 PDF

For professionals and researchers seeking to access the HB 7736.8-2004 standard, it is available in PDF format through various platforms. Ensuring access to the official document is crucial for accurate implementation of its guidelines. Utilizing authorized sources guarantees that users are referencing the most current and comprehensive information.

Conclusion

The HB 7736.8-2004 standard serves as a foundational document in the evaluation of composite material prepreg tack. Its detailed methodologies ensure that materials used in aerospace applications meet the highest quality standards. By adhering to this standard, manufacturers and researchers can contribute to the advancement of composite technologies, ensuring safety, reliability, and performance in aerospace structures.

FAQs

What is the HB 7736.8-2004 standard?

The HB 7736.8-2004 standard, titled “Test Method for Physical Properties of Composite Material Prepreg—Part 8: Determination of Tack,” outlines procedures for assessing the tackiness of composite material prepregs, crucial in aerospace manufacturing.

1 thought on “Understanding HB 7736.8-2004 PDF”